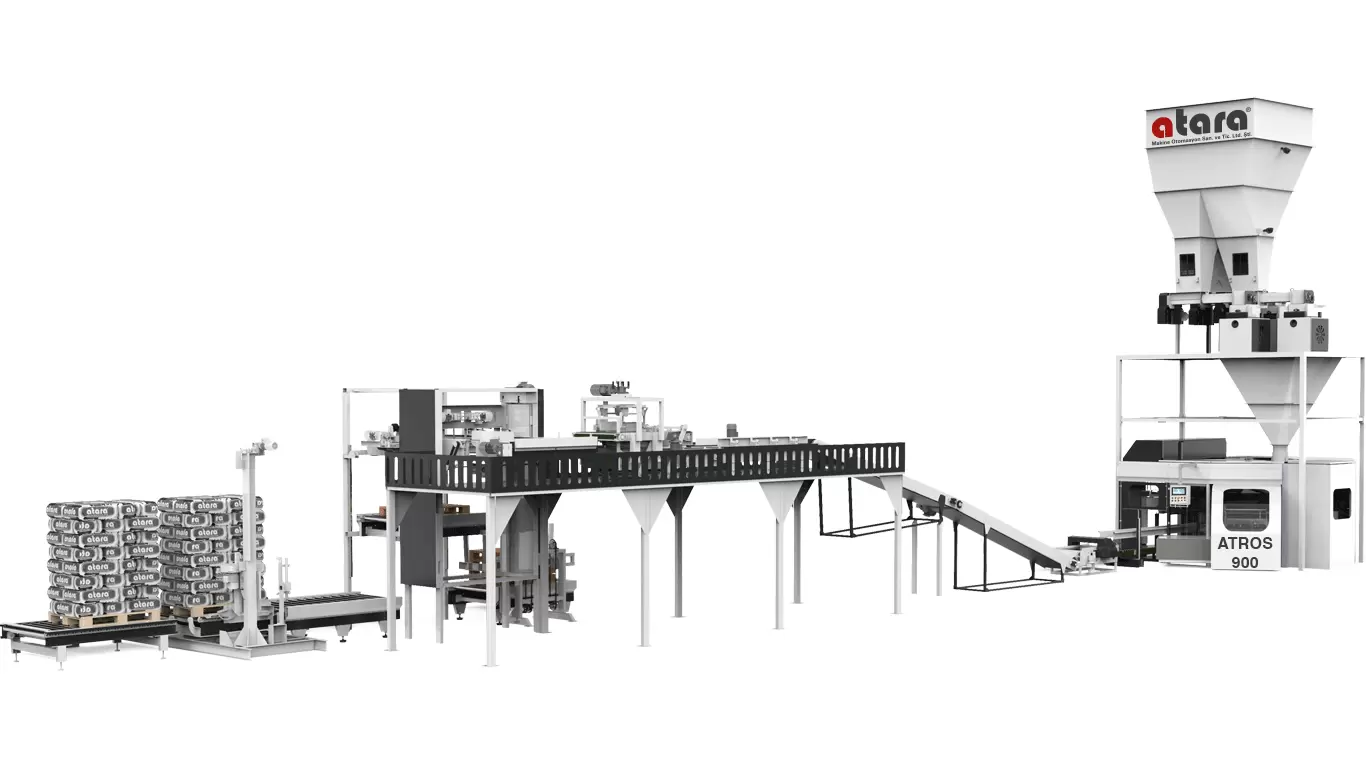

ATROS-900 Robotic Carousel Packaging Machine

- Can be used open mouth bags of polypropylene woven (PP) , polyethylene (PE) bags, paper, plastic, laminated, etc.

- Used for fully automatic filling of flour, feed powder products and grains products with open mouth for 25-50 kg bags.

- Possibility of precise filling by working with different parameters in different products with recipe control.

- All screw motors have a speed controllers.

- Belt conveyor can be easily adjusted electrical to a height of 350-700 mm.

-

Bag conveyor belt motor is speed controlled.

- Sewing machine possibility of adjusting up/down/forward/backward.

- The use of optical sensors minimizes the waste of rope.

- With its emergency stop button and special design, it occupational health and safety rules

- There is a digital capacitive sensor in the flour bunker

- Available for fully automatic high speed bag insertion and closing of bags.

Advantages:

- High performance, precise weighing, high service requirements

- High food hygiene standards

- Low operating and maintenance costs

- High operational safety

- Easy maintenance in short downtimes

- Operator ease of use and wide mobility

| Packaged Product Type | Powder Products |

| Density | 0,55 g/cm³ |

| Weighing Accuracy | ±%0.3 |

| Top Bunker Capacity | 13 m³ |

| Platter Capacity | 0,22 m³ |

| System Pressure | 6-8 bar |

| Power Supply | 380 V AC / 50 Hz |

| Electricity Consumption | 28 kW/h |

| Weight | 10000 KG |

| Air Supply | 150 m³/h |

| Capacity | 900 pack/hour |

Related Products

ATR-125-B Lineer Full Automatic Packaging Line (1-2-5 KG)

It is a line of automatic packaging in finished paper bags with a foldable rectangular bottom weighing 1-2-5 kg. It is intended for the packaging of bulk products of the food industry: Flour, sugar, tea and semolina, etc.

ATR-125-A Lineer Full Automatic Packaging Line (1-2-5 KG)

It is a line of automatic packaging in finished paper bags with a foldable rectangular bottom weighing 1-2-5 kg. It is intended for the packaging of bulk products of the food industry: Flour, sugar, tea and semolina, etc.

Büyükkayacık O.S.B. Mahallesi 513 Nolu Sokak No: 9 Selçuklu/KONYA - TÜRKİYE

+90 (332) 345 02 06

All rights reserved. 2022 - MataBT